Walk through our yard and you’ll notice something straightaway. Row after row, trailer after trailer – same stance, same finish, same details. Like peas in a pod.

That kind of consistency doesn’t happen by accident. It’s the result of tight quality control and disciplined processes designed to ensure every Bailey trailer is built to the same high standard, every time.

For fleet operators, that consistency matters. It affects how your trailers perform, how they’re maintained and their trade-in value. Here’s how we achieve it…

Consistency starts before the first weld

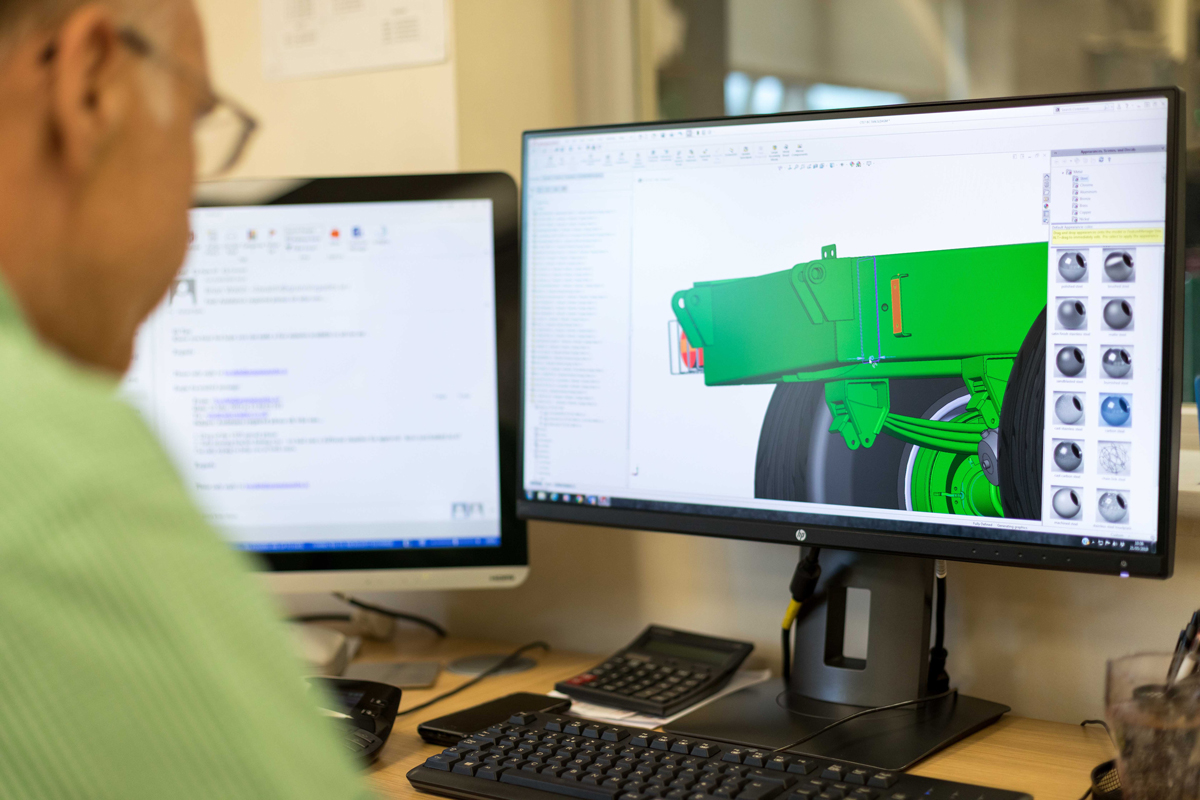

Every trailer we build follows a defined design and specification. Dimensions, materials, components and finishes are standardised and controlled, removing unnecessary variation from the outset. Trailer specifications are constantly reviewed and revised by our design and production teams.

Incoming materials and components are checked to ensure they meet our required quality standards before they reach the factory floor. That early discipline prevents small inconsistencies from turning into visible differences later in the build.

Standardised processes on the factory floor

Each stage of trailer construction follows a defined workflow, with clear responsibilities and repeatable methods. Our teams are trained to work to documented instructions, ensuring the same steps are followed in the same order, regardless of who is on shift.

Rather than relying on individual interpretation, quality is built into the process itself. Tasks are sequenced to reduce variation and key build stages are completed before the trailer moves on to the next phase.

This structured approach means every trailer progresses through the factory in the same way – no shortcuts, no guesswork.

Quality checks that prevent variation

Quality checks are integrated throughout the build, allowing potential issues to be identified and corrected early. Cutting, welding, fitting, finish and functional elements are all reviewed at defined points, ensuring each trailer remains within the expected standard as it takes shape.

If something doesn’t meet that standard, it’s addressed before work continues. That discipline prevents small deviations from becoming noticeable inconsistencies in the finished product.

Before any trailer leaves our factory, it undergoes a final pre-delivery inspection to confirm it matches both the customer’s specification and the quality standard that we expect.

Consistency is a commitment

Tight quality control isn’t about perfection for its own sake. It’s about delivering trailers that meet the same standard, time after time.

By controlling specifications, standardising build processes and embedding quality checks throughout production, we ensure every trailer that leaves our factory reflects the same level of care and craftsmanship.

The result is a fleet of Bailey trailers that don’t just look alike – they perform alike too.

Why uniformity matters to fleet operators

When trailers are built consistently, the benefits extend well beyond appearance.

A uniform fleet:

- Looks professional and cohesive

- Simplifies maintenance and servicing

- Improves parts compatibility

- Delivers predictable performance across assets

Operators know what to expect. Maintenance teams deal with familiar layouts and components. Fleet managers gain confidence that every trailer performs like the last.

That reliability is what “peas in a pod” really means – not just visual similarity, but functional consistency as well.

Don’t just take our word for it

If you’d like to see for yourself how our trailers are built, we offer factory tours for groups of up to thirty people. If you’d like to arrange a visit, please get in touch with us today ››